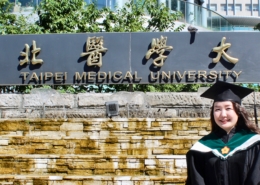

Taipei Medical University develops spider silk based biomedical materials

Source: College of Medical Science and Technology

Published on 2019-11-14

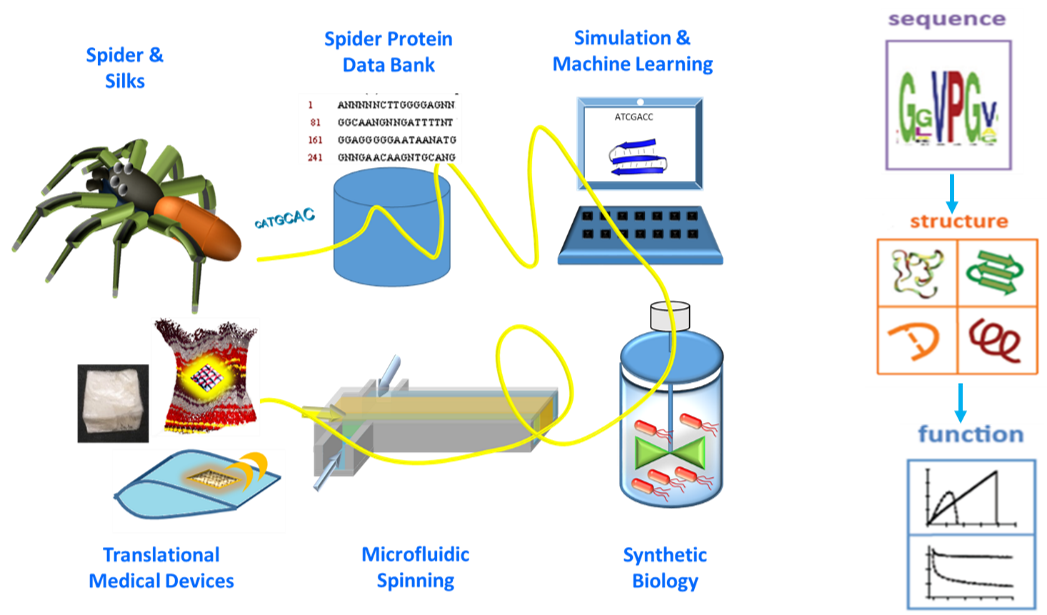

An innovative R&D strategy that mimics nature to carry out material design and synthesis, with the combination of the advanced digital material technology, is aiming to reduce the developmental gap/time between research and product commercialization.

Taipei Medical University, National Taipei University of Technology and National Taiwan University have formed a multidisciplinary research and development team to carry out a cutting-edge research and development on building a digital/computational technology for biomimicking spider silk protein and designing novel silk based biomedical materials. Through the computational platform for deciphering the genetics of spider silk, the team is advancing the research development in biomedical materials as well as translational applications toward medical devices.

Did you know? |

| Biomimicry (i.e. bio-inspired engineering) provides design procedures and systematic structures (or learning architectures) that differ from the traditional materials development by mimicking structures, functions and systems discovered from nature. The Materials Genome Initiative was proposed by the National Institute for Standards and Technology (NIST) in the way that materials based experiments, model simulations, high-throughput calculations and big-data sharing & analyses could be all integrated for the material design, manufacturing and system engineering. |

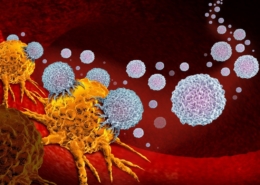

Biological properties of spider silk such as superb biocompatibility, extensibility, tensile strength, toughness, and optical characteristics have made it a popular subject for materials research. Industries/Companies looking at genetic engineering technologies for spider silk production, currently include Nexia Australia & New Zealand, Kraig Biocraft Laboratories and Bolt Threads in the U.S., AMSilk GmbH in Germany, Japan’s Spiber, Sweden’s Spiber Technologies AB, and Orthox in the U.K. As there is no company investigating on the associated technology and development in Taiwan, it is believed that this TMU research team can eventually develop and expand the utility of spider silk products into the applications of biomedical materials and translational medicine. Due to limitations on production volumes and manufacturing capabilities for natural spider silk, synthetic production processes and downstream product development are currently underway with many bottlenecks to be resolved.

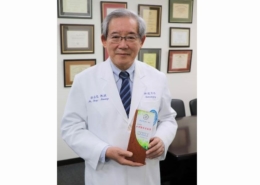

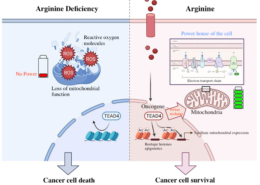

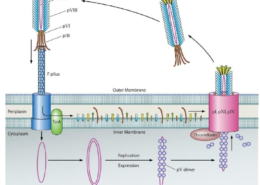

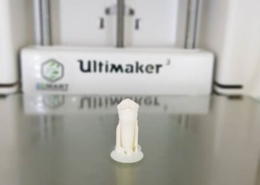

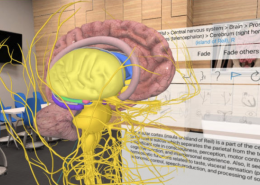

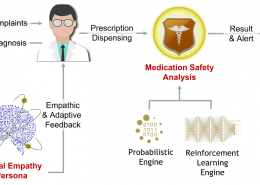

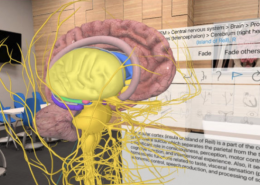

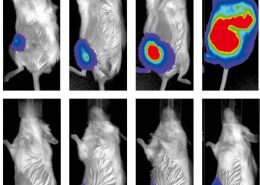

Spider silk has unique physical and biological properties

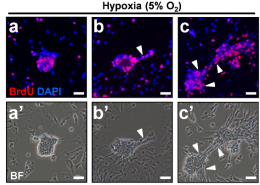

Project leader of the team Prof. Jen-Chang Yang (楊正昌), who leads TMU’s Graduate Institute of Nanomedicine and Medical Engineering, says that the project (entitled Bio-Inspired and Digital Design-Driven Silk Protein Fibers in Design, Synthesis and Fabrication for Translational Research) used the novel spider silk genes as the templates for further genetic engineering and silk protein synthesis.. Mimicking the two-dimensional structural design of spider silk to establish a digitized database platform combining machine learning with AI, the project will start from BioDesign as an initial concept and then subsequently strive to meet clinical needs. The regenerated recombinant spider silk that is designed, synthesized and manufactured through biomimicry technology can be utilized for translational applications in the medical devices business, such as in biodegradable hemostatic cotton, rotator muscle patches, artificial tendons and other medical equipment and products.

Illustration: Conceptual strategy of the project on Bio-Inspired and Digital Design-Driven Silk Protein Fibers in Design, Synthesis and Fabrication for Translational Research

-260x185.jpg)

與連江縣衛生福利局陳美金局長簽署醫療合作備忘錄-260x185.jpg)

期許永續發展成為醫療產業新契機。-260x185.jpg)